1. Introduction: Background and Issues

Any design activities start with an idea that must be transformed into an embodiment of design [1]. Among any design steps, conceptual design exists as the predecessor of core design activities [2]. Existing engineering designs have provided scientific conceptual modeling techniques [3, 4], yet they tended to do such modeling by using complicated way. Each of them placed conceptual modeling as a quantitative method to develop product architectures [5]. Some designers have also been trapped to do premature detailed modeling in conceptual design by purely taking quantitative modeling throughout design activities. Such techniques also required deep analysis that decrease possibilities to do agile design for specific-purposed products with less financial investment in computer-aided tools or any other activities. Therefore, a new modeling approach need to be proposed to overcome those phenomena. New modeling need to incorporate some basic understanding from existing techniques, yet they must be directed by using new ways of application. New modeling approach may also be taken on as visible as possible way for any designers, while it can always produce a feasible design.

2. Literature Review: Logical Underpinnings

The logic behind any modeling activities will always remain same: interpreting an abstract idea by using logical considerations [6]. Some other disciplines such as computer science [7] and project planning [8] have similar logic. They incorporated causal-based reasoning to transform their idea into reality [9, 10]. The most basic logical approach in design field is black box [1]. It provided simple way to understand an observed system by looking at processed inputs and desired outputs. Among other ones, functional [5, 9] and process [6] modeling are two good options to make approach in design activities. They guided designers to discover possibilities on an observed system.

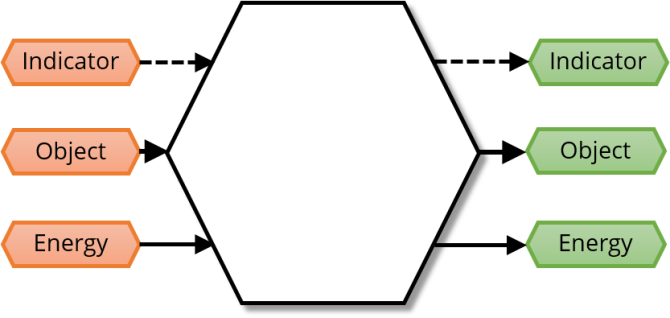

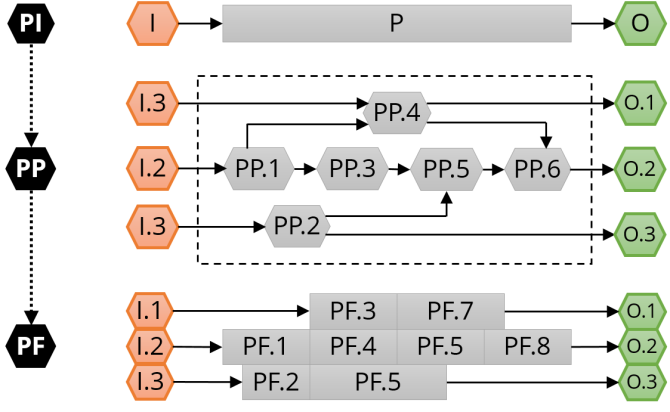

Figure 1. Basic black box

There are three kind of I/O in black box approach (Fig. 1). They are signal, material, and energy [1, 6], as processed entities [11]. Here, signal is introduced as Indicator to deliver strong meaning on indicated information respective indicator for other entities in a system. Material is introduced as Object to avoid misinterpretations with specific type of processing activities [11]. Energy is remain same to underline energy as important facet of any processes. Beside as processed entities, these I/O also act as the basis to understand other entities in an observed system [12]. Any interpretations would always be based on such basis to stimulate uniform definition among designers.

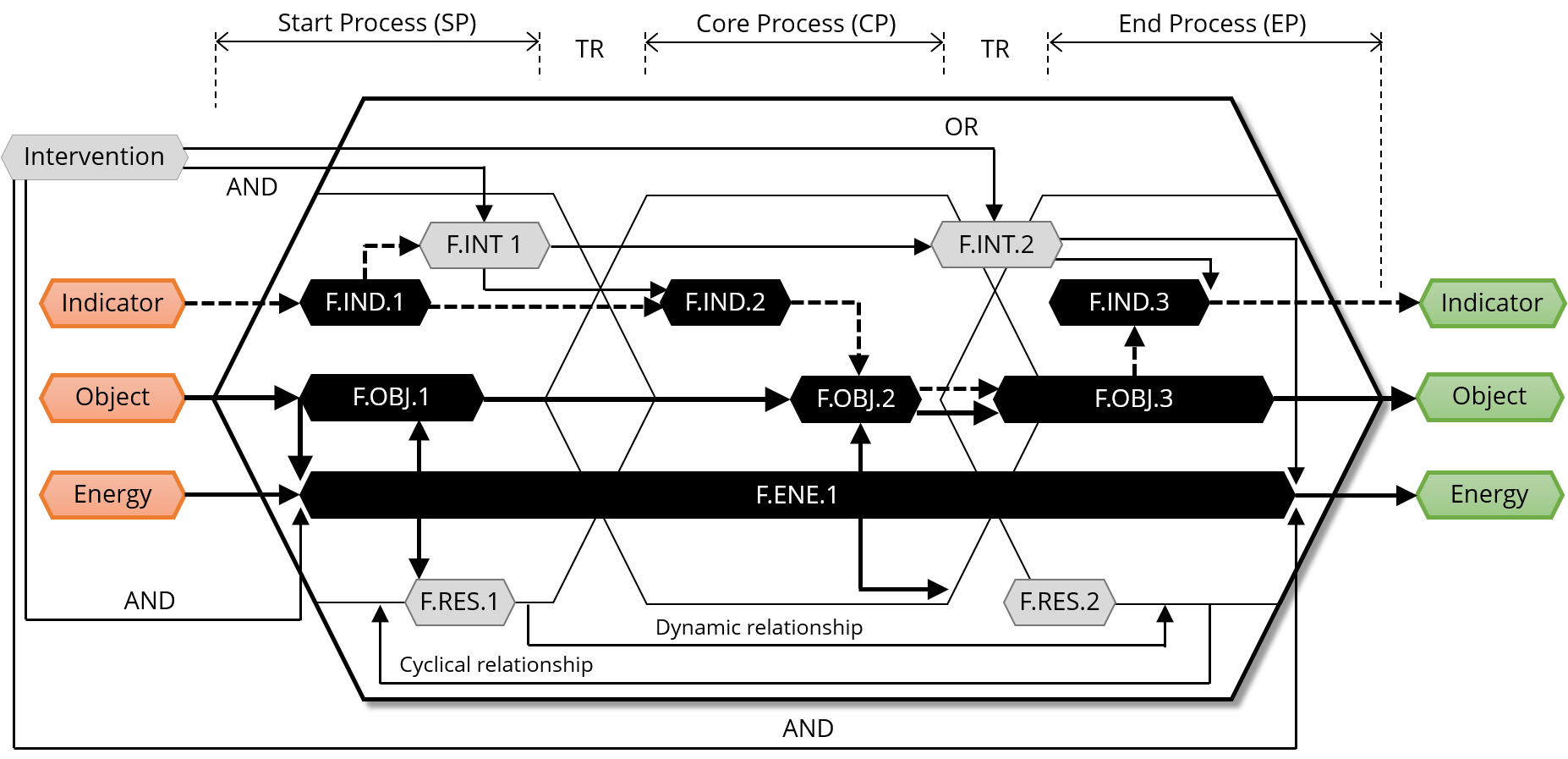

In this study, physiological-based concept modeling is proposed. By incorporating logical thinking from previous techniques [1-2, 5-6, 9-12], a black box framework of physiological concept (Fig. 2) can be constructed. The whole process is exhibited by a system boundary. It covers three types of process: Start (SP), Core (CP), and End (EP) processes. Each of them represents an understanding on how a process act in whole process in order. Furthermore, there are some interventions that may happen along with whole process. Such interventions may act in OR or AND instruction, which describes behavior of intervened entity when it is coupled with two/more discrete inputs. Then residues of observed system may be accommodate by integrating a dedicated function to gather any residues in order to avoid further interferences to the whole process.

Figure 2. Black box framework of physiological concept

3. Physiological Concept: The Approach

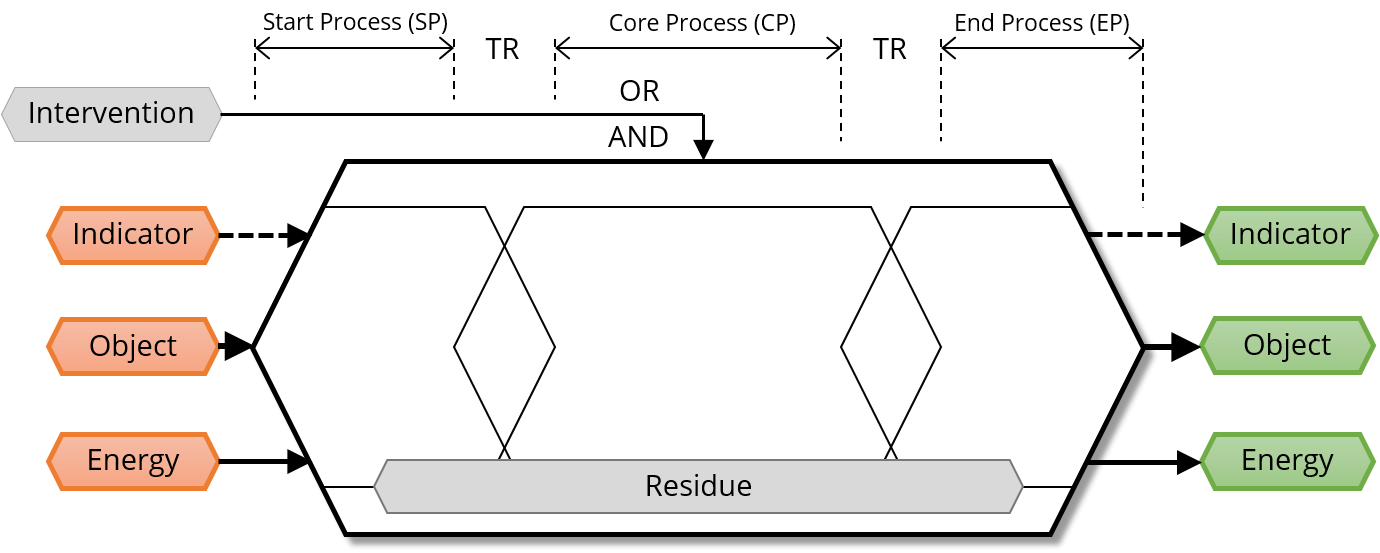

Physiological modeling exists in conceptual design phase, which means that the approach consists of physiological derivation(s) from physiological idea into a conceptual basis of embodiment design (Fig. 3). Thus, physiological idea (PI) is positioned as the highest form of concept, which is further derived into visible modeling levels based on design feasibility. The form of PI is characterized as an I/O model that exhibits global idea of design idea. After that, there are two derivation of PI. The first derivation is the process-based derivation to discover physiological processes (PPs) included in the process (P) facet of PI. The PPs are explored to establish the PI from a set of processes. The flow of a processed input to its respective output(s) is indicated by an arrow to express the connection between processes, including discrete I/O model for each process. Then, by looking at established PPs, physiological functions (PFs) are developed. Each PF means that a PP is handled by function(s) which exhibit a process in the form of feasible function(s). Such independent handling with feasible function indicates that each function must be included into whole design by developing a cloistered mechanism that is feasible to be built and can transform incoming inputs to required inputs by next PF through its position as a discrete I/O entity. Thus, by establishing a set of PFs, all PPs can be completely handled through all required functions to actualize the whole process.

Figure 3. Physiological derivation

Such derivations are drawn into a visible modeling to exhibit the desired hierarchy of physiological concept (Fig. 4). The diagram indicates a complete mapping of PPs and PFs as a whole PI. It is established by taking all PPs and PFs and their connections based on black box framework of physiological concept (Fig. 2). As the whole process, PI is exhibited by the largest area covering whole process since the beginning until the end of targeted process. It covers global idea of transformation (Fig. 2) from incoming inputs to desired outcomes including some interventions. The area covered by PI is the boundary of whole process, which means that inputs, outputs, and the source of interventions discovered on physiological derivation are excluded, yet they are connected to related functions inside PI to express their incoming/outgoing flow to/from internal PPs.

Inside such PI, discovered PPs are drawn based on their order in transforming inputs to outputs. Even though there are three basic types of process order (Fig. 2), the number of process must always be based on the number of PPs previously discovered. Such consistency is required to maintain the linearity of logic behind this modeling. However, dynamic process may require flexible reorder of processes, which means in some situation the order of process can be ignored yet logical linearity must be maintained by keeping connection of discrete I/O among PFs. In a continuous process, correlation between processes in a normal set-up is expressed as the cyclical relationship between process orders that also exhibits continuous correlation with external entities. On the transition areas, connections between external entities such as inputs, outputs, and interventions, to internal functions can exist as some PPs and PFs discovered in physiological derivation may happen as the result of desired transformation process.

After that, each PF is placed inside its respective process. In Start Process (SP), Core Process (CP), and End Process (EP), there are some possible functions based on relationship with respective input. The first is function of indicator (F.IND) that acts the indicator of behaviors of monitored process, as the controller of some behaviors of related processes, or as the indicator of feedbacks to other kind of functions due to some interventions. It can also give inputs for later processes, which require information transmitted through such function. The second type of function is object actuator (F.OBJ) that acts as the transformed input. It can also push information for function of indicator to report its own behaviors or to request required action(s) regarding previous behavioral changes and/or later desired ones on respective object. The last kind of functions is function of energy (F.ENE) that express required energy as well as energy transmissions throughout whole process. It can be single energy source, hybrid (two energy sources), or multiple sources, following the derivation of PI into PPs. Usually, function of energy is continuously active in all kind of processes to keep whole process running, yet systems with multiple energy sources may have some F.ENEs which act alternately.

Figure 4. An example of physiological model

On the other side, some interventions may happen. The most important interventions are process starter and killer. Starting the whole process requires action from outside, which means that an intervention must be happened in the beginning just before whole process is began. It may be coupled with other input from other kind of functions as safety feature and/or locker to keep whole system running. The second one is process killer to cut off last process. It may also be coupled with other functions. In addition, some interventions can also be included as additional functions. Such additions (F.INT) may be required to avoid sudden phenomena such as crash or power failure. Usually, each of them receives push-information from outside entity such as sensor or human guide, yet it may also receive information to do its function from other PFs inside any PPs. Some later PFs may require outcomes from such function of intervention that resulted from processed inputs from other previous PFs. Despite of its characteristics as semi-outside entity, some internal function of interventions may also be positioned as automatic interventions to deliver better performance of whole process by taking responsibility to change the behavior of any affected functions in continuous and/or dynamic situation. Then, function of residue (F.RES) may also be required to accommodate residues of related process. It is required to avoid side outputs from any functions to escape from whole process in order to keep the closed loop of targeted system. Residues from internal functions can be anything, including heat, emission, waste, noise, etc. In short, function of residue is the handler of excess outputs produced by internal process due to unprocessed output from a function and/or discontinued flow between functions.

4. Case Study: Modeling a Competition-based Electric Car

In order to understand physiological concept, a case study is taken. Observed process is a competition-based electric car. It is taken as an appropriate case due to following reasons: (1) electric car is a fairly new idea, which means that physiological concept can stimulate a more visible modeling and feasible design; (2) competition-based product is potential to be smartly observed due to unique characteristics of each product which are constrained by listed rules and regulations in different competitions; (3) a fairly new idea in a constrained situation will emphasize physiological concept as effective way to do a visible modeling in producing feasible design based on constrained specifications. To deliver strong focus on the idea of physiological concept, the discussions of such case are explained on the map of physiological concept for observed product.

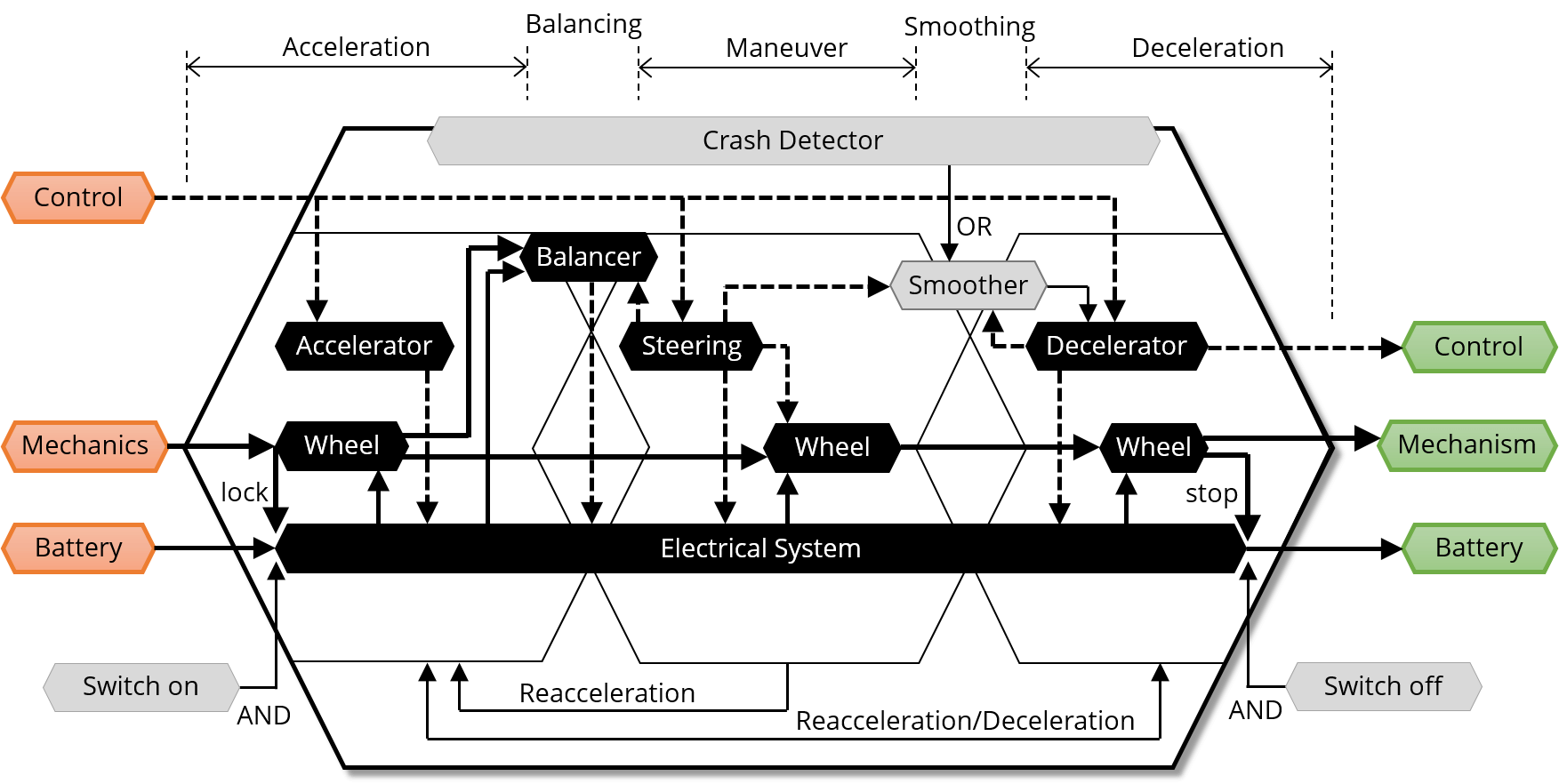

Figure 5. Basic physiological concept of competition-based electric car

The observed product is an electric car for a racing competition. The whole process is simply defined as race activity. On such activity, if we convert it into a visible physiological idea, the boundary for the activity is since the engine is turned on until it is turned down. Therefore, there are three PPs can be derived: acceleration, maneuver, and deceleration. The first PP is further derived into four PFs including one transitional function. Whole process is turned on by using Switch-On intervention that is coupled (AND) with Lock sensor at Wheel as safety feature. Accelerator become function of indicator, which is controlled by human to accelerate whole system. It push information for Electrical System, which then convert electrical energy into mechanical one and transmit it to Wheel. To balance acceleration when it comes to Maneuver process, a transitional function Balancer works by processing information on Electrical & Wheel conditions coupled with Steering control. It will push information to Wheel to balance acceleration with agile maneuver. The Steering also independently gives inputs to Electrical and Wheel to push instruction on the Maneuver process, while Wheel will further receive transmitted energy from Electrical System. Besides, it push coupled information (OR) with Crash Detector to an internal function of intervention “Smoother”. When an input from Crash Detector, Steering, or Decelerator is received, Smoother will re-instruct Decelerator to gradually decelerate energy processing in Electrical System, which then smoothly affects Wheel. Besides, re-acceleration/deceleration may happen in dynamic ways between processes. Then, whole process is turned on/off by coupling Stop sensor at Wheel and Switch-On/Off intervention.

5. Conclusions: Propositions and Insights

Physiological concept modeling is characterized as a visible modeling to produce a feasible design. It delivers easy-to-imagine conceptual design by deriving global idea into visible functions, which are feasible to be detailed in next design stage as well as constructed to become real product. By looking at previous explanations, there are some steps required in conducting physiological concept modeling in order to produce a visible model that is feasible to be further actualized:

STEP 1 — Establishing basic black box for targeted process (Fig. 1)

In this step, modeler determine global idea of observed process by specifying required inputs and desired outputs as the basic boundary of whole process.

STEP 2 — Converting basic black box into a physiological idea (PI, Fig. 3).

Global idea established in the first step must be converted into a visible idea, which means that whole process must be characterized as a feasible model to be actualized.

STEP 3 — Deriving physiological processes (PPs, Fig. 3)

Such inputs and outputs are transformed to a set of processes that is limited by the boundary of whole system based on physiological idea (PI).

STEP 4 — Discovering physiological functions (PFs, Fig. 3)

The results of derivation on PI are further derived to discover feasible functions as the handler of discrete processes. Functions are the actualization of desired processes.

STEP 5 — Developing physiological concept (Fig. 4)

All results of physiological derivation are depicted as a map of physiological concept, which exhibits: (a) the order of processes; (b) correlation and connection between two/more processes; (c) the basic understanding of physiological behavior throughout the whole observed process due to influences between internal processes and possible interventions, from either outside or within, in either static, dynamic, or continuous setting of situation.

Then, other researchers are encouraged to apply the approach proposed in this study in their own cases. Although each application may different with the case study provided in this paper, both in project and product types, the approach is remain same as it generalized understandings in discussed idea. The team of authors would welcome any request through corresponding author to discuss and/or supervise such applications. Some interesting cases may be included in next publications related to proposed idea. Researchers are also encouraged to adapt the idea in this study in specific field of studies. Broader adaptations would enrich the body of knowledge of related fields. Integration to existing design methodology would also be interesting to investigate in further research.

References

- Pahl, G., Beitz, W., Feldhusen, J., Grote, K-H. (2007). Engineering design: A systematic approach, 3rd ed. Berlin, DE: Springer Verlag.

- Ülrich, K.T., Eppinger, S.D. (2012). Product design and development, 5th ed. New York, US: McGraw-Hill.

- Belaziz, M., Bouras, A., Brun, J.M. (2000). Morphological analysis for product design. Computer-Aided Design, 32(5), 377-388.

- Hsiao, S-W., Chiu, F-Y., Lu, S-H. (2010). Product-form design model based on genetic algorithms. International Journal of Industrial Ergonomics, 40(3), 237-246.

- Stone, R., Wood, K., Crawford, R. (2000). Using quantitative functional models to develop product architectures. Design Studies, 21(3), 239-260.

- Nagel, R.L., Hutcheson, R., McAdams, D.A., Stone, R. (2011). Process and event modelling for conceptual design. Journal of Engineering Design, 22(3), 145-164.

- Meier, R., Chaill, V. (2005). Taxonomy of distributed event-based programming systems. The Computer Journal, 48(5), 602-626.

- Westland, J. (2006). The project management life cycle. London, UK: Kogan Page.

- Tor, S.B., Britton, G.A., Zhang, W.Y., Deng, Y.M. (2002). Guiding functional design of mechanical products through rule-based causal behavioural reasoning. International Journal of Production Research, 40(3), 667-682.

- Sianipar, C.P.M., Taufiq, H., Estiningtyas, H.R., Dowaki, K., Adhiutama, A., Yudoko, G. (2013). Materials selection in appropriate technology: Four focuses in design thinking. Advanced Materials Research, 789, 379-382.

- Dieter, G. (1991). Engineering design: A materials and processing approach, 2nd ed. New York, US: McGraw-Hill.

- Sianipar, C.P.M., Yudoko, G., Dowaki, K., Adhiutama, A. (2013). Design methodology for Appropriate Technology: Engineering as if people mattered. Sustainability, 5(8), 3382-3425.

Sianipar, C.P.M., Yudoko, G., Dowaki, K. (2014). Physiological concept: Visible modeling for feasible design. Applied Mechanics and Materials, 493, 432-437.